Volumetric Modular Construction

Volumetric modular construction is an innovative, sustainable construction delivery method utilizing offsite, lean manufacturing techniques to prefabricate single or multi-story whole building solutions in deliverable module sections. Permanent modular construction (PMC) modules can be integrated into site built projects or stand alone as a turn-key solution and can be delivered with MEP, fixtures and interior finishes in less time—with less waste, and higher quality control compared to projects utilizing only site-built construction.

What is Volumetric Modular Construction?

The modular construction process includes offsite construction of modules or building units that are delivered to a single/fixed location. The modules are 60% - 90% completed in a controlled plant environment and then delivered on site. As the name suggests, this construction is a permanent structure and typically will not be re-located as per the owner’s need. Therefore, occupants planning for a long-term stay at one fixed location are best suited for permanent modular construction. Examples of permanent modular construction include healthcare facilities, hotels, schools, and K-12 education facilities.

Once the modules have been built, they are shipped to the site and fastened together. The final construction stage includes completing mateline finishes, exterior systems such as cladding and roofing components and internal spaces like lobbies, stairwells, elevator shafts and anything else that is unable to be completed in the factory. The beauty of the finished building is that occupants will not be able to tell how the structure was built.

Advantages of Modular Construction

From factory precision to faster installation, modular construction offers an attractive range of advantages.

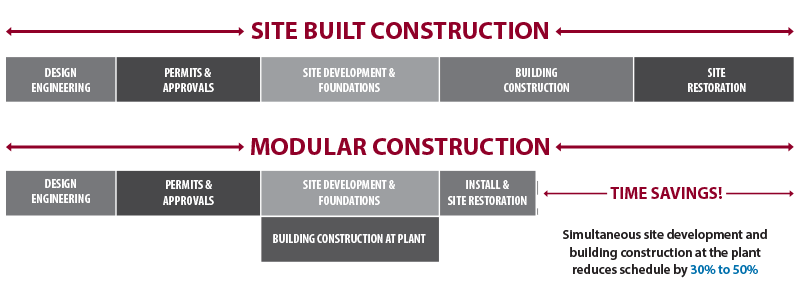

Time Savings

One of the biggest benefits of modular construction is that it offers an accelerated schedule. While modules are built in controlled offsite location, site work can occur at the same time. As illustrated above, parallel construction work can be performed in the modular construction process. This modular process allows reduced construction times of about 30% - 50% that of conventional construction. In the process of modular construction, floors, walls, ceilings, rafters, and roofs can be constructed simultaneously. On the other hand, during conventional construction, walls cannot be set until floors are in position; additional floors, ceilings and rafters cannot be added until walls are erected.

Sustainability

Modular construction makes it possible to optimize construction materials purchasing and usage while minimizing onsite waste and offering a higher quality product to the buyer. According to the UK group WRAP, up to a 90% reduction in waste can be achieved through the use of modular construction. Materials waste minimized includes wood pallets, shrink wrap, cardboard, plasterboard, timber, concrete, bricks, and cement.

The modular structure is constructed off-site simultaneous to foundation and other site work, thereby reducing the time and impact on the surrounding site environment, as well as reducing the number of vehicles and equipment needed at the site.

When the owner’s needs change, some modular buildings can be disassembled and relocated or refurbished for their next use, thus reducing the demand for raw materials and minimizing the amount of energy expended to create a building to meet the new need.

Modular buildings can also contribute to LEED requirements in the same categories as traditional, site-built construction, and can even provide an advantage in the areas of sustainable sites, energy and atmosphere, materials and resources, and indoor environmental quality. Modular construction can also provide an advantage in similar categories in the International Green Construction Code.

Quality

Modular construction is process-oriented construction which lends itself to be more efficient. Modular buildings are built with all the same materials and to the same building codes and architectural specifications as traditional onsite construction, but in an indoor quality-controlled environment. Just like a car assembly line, a prefabricated building module has built-in quality checks. Modular building factories are dedicated to crafting highly efficient buildings with inspections at each station, eliminating variability in decisions or unexpected complications that can occur in the field.

Because modular units must be trucked long distances and then moved by crane or other method onto a foundation, they must also be extremely structurally sound. Hence, modular buildings can be more durable than structures built onsite.

Other Benefits

Other advantages of volumetric modular construction include:

- More controlled conditions for weather, resulting in fewer delays

- Material quality maintained in a secure environment

- Permanent, skilled workforce with extensive training

- Improved supervision of labor

- Easier access to tools and fewer material deliveries

- Assembly of building components off-site while permits are being processed and site preparation is taking place

- Reduced on-site disruption – the last phase of the modular construction process is setting the modules on site, followed by the final finish-out of the interior and exterior of the building

Learn More About Volumetric Modular Construction Projects

4233 Chesnut Street, built by Volumetric Building Companies

4233 Chestnut in Philadelphia is a marvel of volumetric modular design, engineering, manufacturing, and construction. At over 133,000 square feet of modular building, the building was the largest wood-framed modular construction project on the east coast upon completion.

A-LINX: Modular Building for the Future

With the price of building materials steadily climbing, any advantage in construction is huge. Modular construction, in particular, is offering significant advantages in a rapidly evolving industry. Consistency, efficiency, and overall speed are some of the main advantages of modular, and A-LINX Building Technologies is taking it to the next level.

Upcoming 2026 Offsite Construction Network Events

Join the leading companies and professionals from across the offsite construction industry at each of this year's Offsite Construction Network events. With summits and expos taking place across North America in 2026, it's never been easier to connect with and learn from offsite construction manufacturers, designers, builders, and suppliers from the United States and Canada.

Subscribe today to get the latest updates on future events from the Offsite Construction Network.